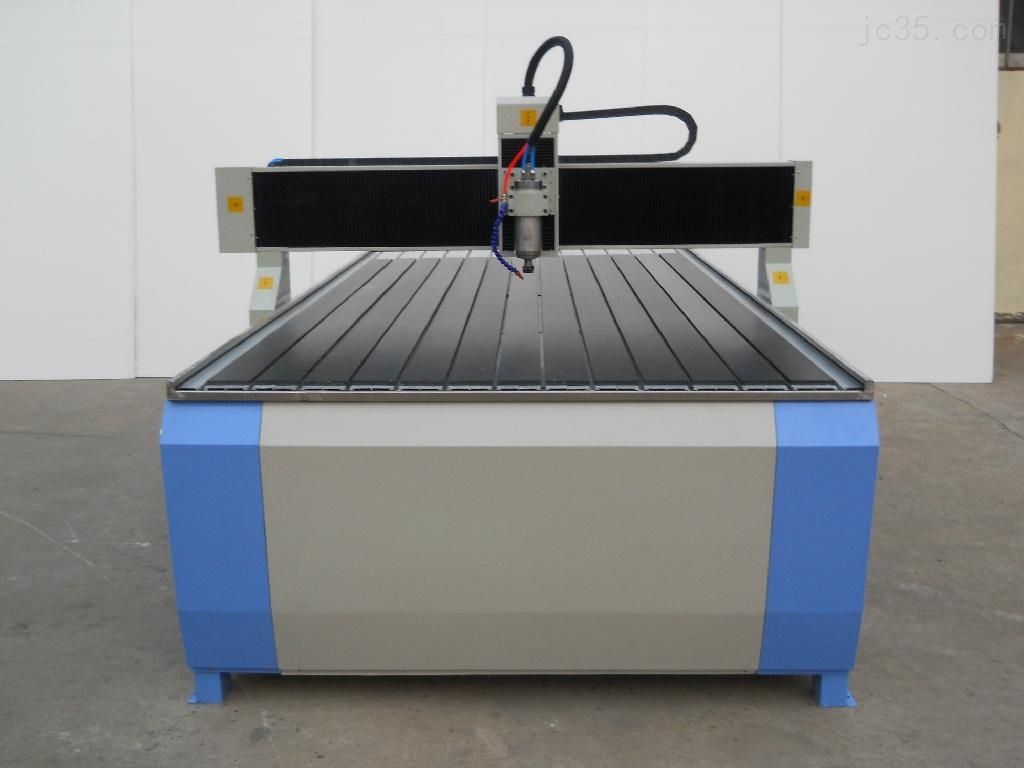

The Application Characteristics of Closed Loop Stepping in Engraving Machines

Time : 12/9/2023 9:08:16 AM

Abstract: The two most important indicators for customers to evaluate the performance of engraving machines are: (1) processing speed; The processing speed directly affects production efficiency, and the higher the processing speed, the higher the production efficiency. (2) Stable operation and long-term processing without misalignment. If there is any misalignment during the processing, it will cause waste of processing materials. For precious rosewood materials, customer losses will be significant, and customers hope that there will be no misalignment to reduce processing losses.

1、 The two most important indicators for customers to evaluate the performance of carving machines are:

(2) Stable operation and long-term processing without misalignment. If there is any misalignment during the processing, it will cause waste of processing materials. For precious rosewood materials, customer losses will be significant, and customers hope that there will be no misalignment to reduce processing losses.

2、 The stepper motor is the main transmission mechanism of the engraving machine. Due to the high-speed characteristics of the stepper motor, the torque of the stepper motor decays quickly at high speed. That is to say, the higher the machining speed of the engraving machine, the smaller the output of the stepper motor. To ensure stable engraving processing, the acceleration of the engraving machine cannot be turned too fast. If the machining speed is too high, the stepper motor will lose its step, causing machining misalignment. When the spindle gets stuck and the load increases, it can cause the stepper motor to lose frequency, and there is a risk of misalignment in the engraving process.

3、 The use of closed-loop stepper motors can effectively improve the overall performance of the engraving machine. As the stepper motor machine is closed-loop controlled, the driving part can monitor the working status of the stepper motor, achieve precise positioning, adjust the stepper motor current according to the load size, achieve intelligent control, and effectively avoid the problem of step loss in the stepper motor, which can effectively improve the machining speed of the engraving machine.

With the continuous improvement of customer requirements, the subsequent open-loop stepper motor can no longer meet industry requirements, and there is a trend for closed-loop stepper motors to replace traditional stepper motors in the future