Application in the screw machine industry

Time : 2/19/2024 3:18:18 PM

Application background:

Locking screws are an important assembly process that is applied in industries such as 3C electronics, household appliances, automotive assembly, plastics, toys, etc. The locking effect directly affects product quality. Before the emergence of automatic screw locking equipment, the screwing work on production lines mainly relied on manual labor

In recent years, the downstream industry market has experienced explosive growth, giving rise to a demand for large-scale, high-precision, and complex screw locks. Traditional manual locks are difficult to meet the requirements in terms of efficiency and technology

In order to achieve a dual upgrade of production capacity and technology, more and more manufacturers are choosing to introduce automatic locking screw equipment

Equipment introduction:

The automatic screw locking machine uses various electric and pneumatic components to complete the automatic gripping, conveying, alignment, tightening, detection and other processes of screws. This equipment can simplify the screw tightening process and achieve standardized and consistent production processes

The equipment consists of an automatic nail feeding mechanism, a locking mechanism, a power electrical box, and a positioning system. According to the working principle, it can be divided into multi axis locking screw machines and desktop locking screw machines

Devison Plan:

Introduction to the plan

The Devison Lock Screw Machine Solution is a new generation industry customized solution developed based on the P100S series servo driver. The locking shaft application is configured with "P100S series servo driver (electric screwdriver special version)+servo electric screwdriver", which can achieve high-speed and high-precision locking with an error of 0.05N M

It has the characteristics of comprehensive functionality, fast data exchange, high accuracy, wide applicability, and easy debugging

Applicable scope

Desktop and multi axis machines

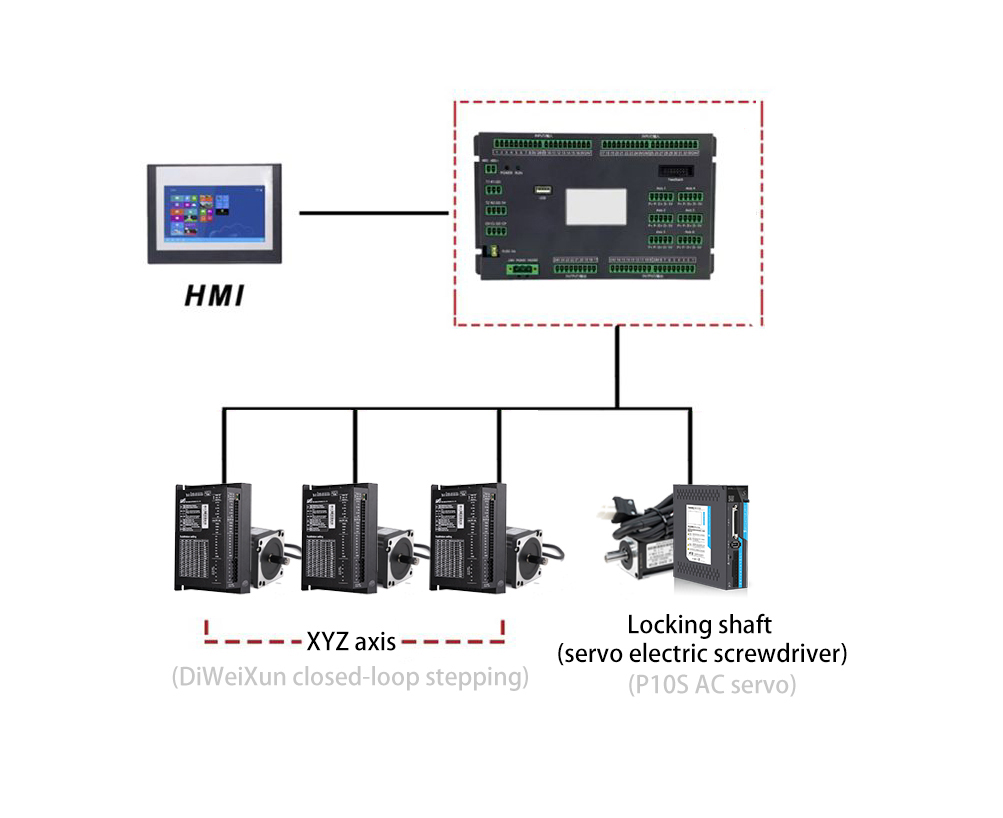

Universal Configuration System Topology

Highlights of the plan:

1. There are two locking modes: torque and number of turns

2. Float high and slip tooth alarms interact with the upper computer signal to determine whether the next action is to hit again or continue

3. Built in 16 customized process parameters, can be switched through I or 485, and a product supports multiple torque locking processes

1. Supports multi stage speed control (default three stage speed lock attachment), high efficiency, high precision, and torque stability

2. Support torque repair, position locking, and automatic judgment of locking screw engagement function

3. Multiple reversal modes to meet different process requirements

4. The stationary state can be selected and the locking force can be set

5. Historical data can be memorized, queried, and exported

6. The LED panel displays real-time torque and locking time (requires the selection of a dedicated distribution batch screen)

7. The motor has a small size and is suitable for high demand positioning situations