Woodworking carving machine solution

Time : 2/20/2024 8:51:59 AM

Application background:

Woodworking carving machines are mainly used for woodworking, crystal, copper, aluminum, etc. Make it more aesthetically valuable.

Application 1

Straight row tool change machining center/disc tool change machining center: mainly completes the pulling angle on the door panel, milling various patterns on the door panel or cabinet door, and cutting the small board planned on the menu layout software;

Application 2

Four process cutting machine: complete the milling of patterns in the cabinet and cut the small boards planned on the menu layout software;

Working principle:

Develop production plan

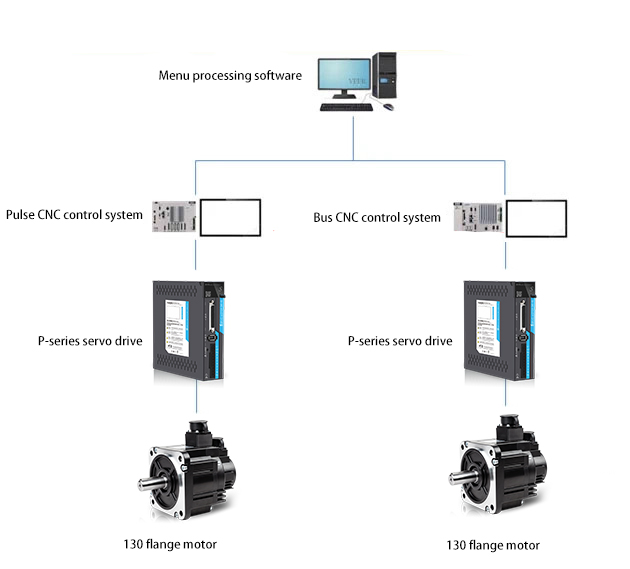

The menu software will optimize layout (minimize scrap rate) and generate processing path files

The CNC system parses the machining path into G-codes that can be recognized separately

Upper raw material board

The CNC system controls the X/Y/Z axis to complete the planned path

Process various shapes that need to be milled and cut them out

Pushing cylinder pushes material

Fast (X/Y axis at 80-100 meters/minute)

Ultra high cost performance ratio

Batch copying and easy after-sales service

High requirements for milling consistency and stability

Devison Plan:

Becoming a leader in efficient and easy-to-use servo and stepper products