Solder paste printing solution

Time : 2/20/2024 10:17:35 AM

Application background:

Application background:

Solder paste printing is the front-end technology of electronic component surface mount technology (SMT), which involves coating a certain amount of material (solder paste or adhesive) on the surface of a PCB board to tightly bond the components and maintain good conductivity.

People's daily use of electronic appliances such as mobile phones, computers, and smart home appliances has all undergone this process during the circuit board assembly stage.

Development trend of solder paste printing industry

Lightweight and multifunctional terminal products (market)

Inducing birth

Production assembly (technology) miniaturization and high density

requirement

Solder paste printing equipment with high precision and stability

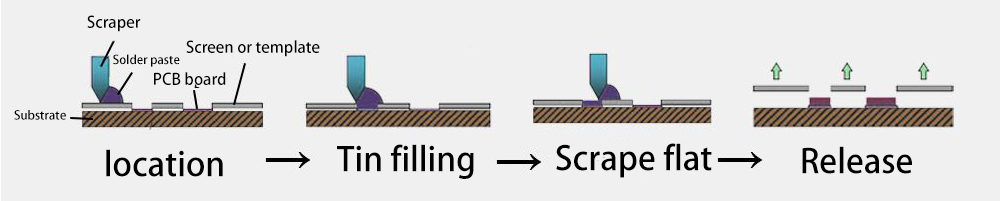

Working principle:

1. Fix the PCB board onto the substrate, and place the steel plate with a printed graphics window flat on top of the PCB board (leaving a gap).

2. The substrate supports the PCB board and the steel plate move vertically upwards to the designated position. A scraper with solder paste is used to scrape the steel plate, and the solder paste flows down the steel plate with the action of the scraper, filling the cut and leaving a mark on the surface of the PCB board.

3. Separate the steel plate from the PCB board, and ultimately leave an image composed of solder paste on the PCB board.

User pain points:

01 Inaccurate alignment

02 Insufficient substrate support

Devison Plan:

Introduction to the plan

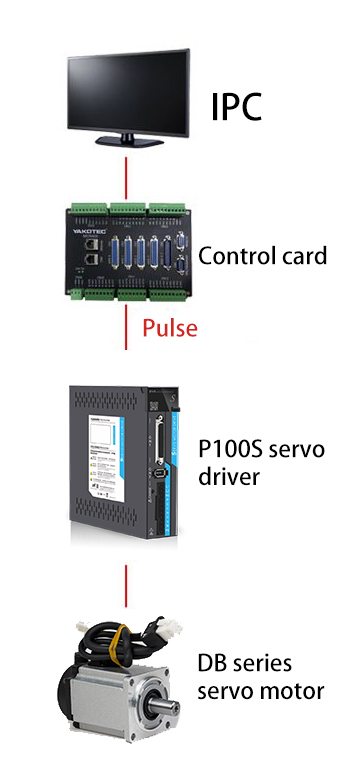

Both the X, Y, and Z axes adopt the Divxun P series same server system and pulse control, supporting multiple control modes such as position, speed, and torque.

It has the characteristics of high precision, fast response, short stop time, and smooth operation, which can effectively solve a series of unstable printing effects caused by factors such as misalignment and insufficient support. The motor can accelerate up to 3000r/min, significantly improving production efficiency.

Plan details

Highlights of the plan:

More diverse functions

Supports multiple control modes such as position, speed, and torque.

More convenient to use

Plug and drop crimp terminals, equipped with LED display panels, with less wiring and easy debugging; After the initial debugging of parameters, the output is stable with less maintenance.

■ More precise positioning

The CCD motion part is controlled by a servo system, equipped with a 21 bit magnetic/optical encoder scheme to ensure accurate alignment and effective printing of solder paste, templates, and solder pads.

■ More stable and smooth operation

Equipped with four sets of notch filters, the CCD Y-axis long screw operates smoothly and without any abnormal noise at low speeds.

The Z-axis of the platform adopts a 750W servo system, which controls smoothly and prevents solder paste deposition due to insufficient substrate support.

■ More efficient production

The X-axis and Y-axis can be quickly positioned within 30-50ms, and the motor can accelerate up to 3000rpm as needed, effectively improving production efficiency.

■ Safe and reliable

The drive is equipped with dynamic braking function, and even after power failure, the Z-axis still maintains a gentle descent to avoid collisions and protect the equipment.